- Product Name: Semi-welded plate heat exchanger

- Product Classification: Semi-Welded PHE

- Company name: Qingdao Hiwell Machinery Co., Ltd.

- Contact Address: Room 2707 Zhaoyin Mansion, 36, Hongkong Middle Road, Qingdao 266071, China

- Add time: 21/01/04

Product Details

Product inquiry

Semi-welded plate heat exchanger

Why semi-welded type?

Gasketed plate heat exchanger reaches its limits when it comes to aggressive media for which the use of gaskets is not suitable. We provide semi-welded plate heat exchanger in this circumstance. It is widely used in the evaporation and condensation of ammonia and freon refrigerant, industrial evaporation and condensation, water-cooled oil cooler, and general cooling and heating of high temperature, high pressure and strong corrosive media in one channel.

-

Advantages

-

It has all the advantages of a conventional gasket plate heat exchanger has.

-

It solved the problem that when the medium in one side of the conventional gasket plate heat exchanger is corrosive, and the rubber gasket cannot meet the requirements.

-

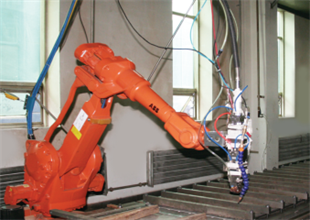

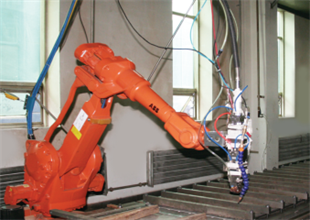

It does not require frequent replacement of gaskets which lowers the operating cost. Laser welding is used for sealing and replaces conventional gaskets on the process material side thus largely reduces the procurement of spare parts.

Our semi-welded plate heat exchanger adopts the world's most advanced laser welding machine and modern laser beam welding process. Compared with other welding methods, laser beam welding process has the advantages of little deformation after welding, high welding quality, and small stress. It is particularly suitable for high pressure and corrosive conditions.

Our semi-welded plate heat exchanger adopts the world's most advanced laser welding machine and modern laser beam welding process. Compared with other welding methods, laser beam welding process has the advantages of little deformation after welding, high welding quality, and small stress. It is particularly suitable for high pressure and corrosive conditions.

Main parameters

* Pressure: Maximum design pressure is up to 30 bar.

* Temperature: Maximum operating temperature is up to 200℃ ,

minimum operating temperature is-40℃ .

* Corrosion: Resistant to most aggressive media.

Semi-welded PHE MaterialChannel plates

SS304, SS304L, SS316, SS316L, SS317L, SS321, 254SMO, Titanium, N200/201, Hastelloy C-276, Hastelloy C-2000, Hastelloy G-30, 904L.

Plate thickness: 0.6mm, 0.7mm, 0.8mm

Gasket material: EPDM, Nitrile, Chloroprene, Fluororubber

Other materials suitable for special working conditions are available as required.

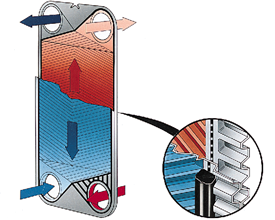

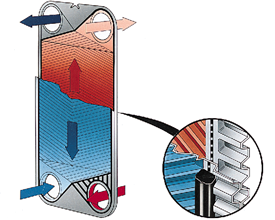

Working principleChannel plates

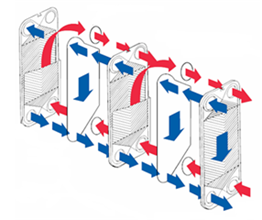

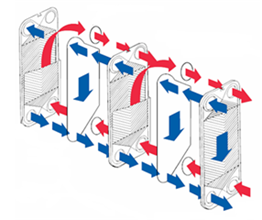

Semi-welded plate heat exchanger consists of a series of cassettes, which formed by two plates laser welded together along the sealing groove. The aggressive medium flows inside the cassette, only in contact with a special designed ring gasket. Each cassette is fitted with a gasket. The other medium flows in the gasketed channels. Two media flow reversely in adjacent channels, between which heat transfer will take place.

Structure

Two main parts: cassettes and frame.

Cassette is the core component of semi-welded plate heat exchanger. The frame consists of fix frame plate, movable pressure plate, carrying bar, guide bar, and thread rods.

Cassettes are assembled between a fixed frame and a movable pressure plate and compressed by tightening bolts.